Forefront technology for advanced waterjet cutting

Waterjet specialists at your service.

We build quality machines specific to your needs, with lifetime support. Today we serve customers in more than 40 countries around the world.

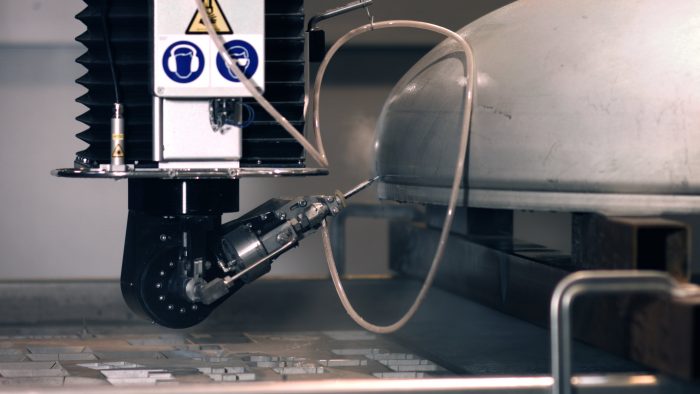

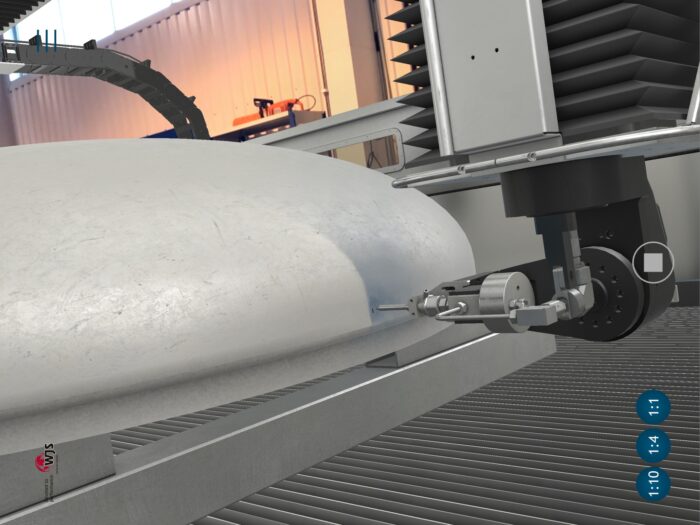

FiveX / FiveX Ultra

Frontline technology for advanced free form 3D cutting

FiveX machines are commonly used in high tech industry sectors, built with our most advanced technology. They repeatedly perform high precision ± 0-120˚ cutting for full 3D processing. Largely embraced by the Defense Industry, Space Industry, Aerospace Industry and Power Industry.

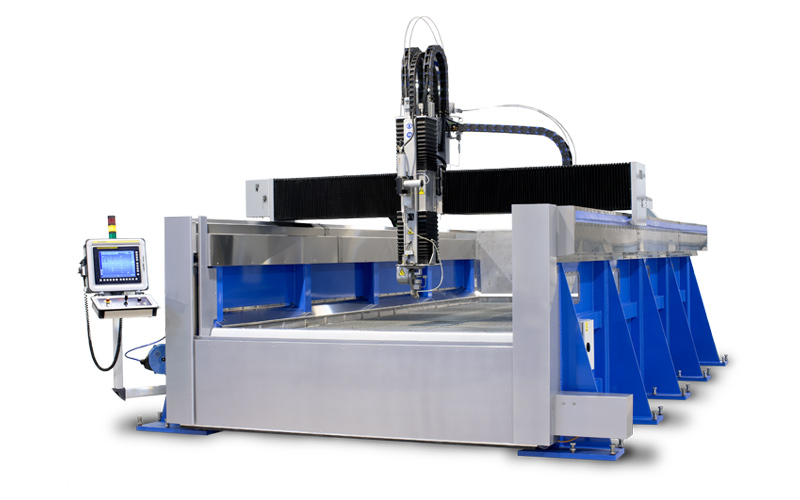

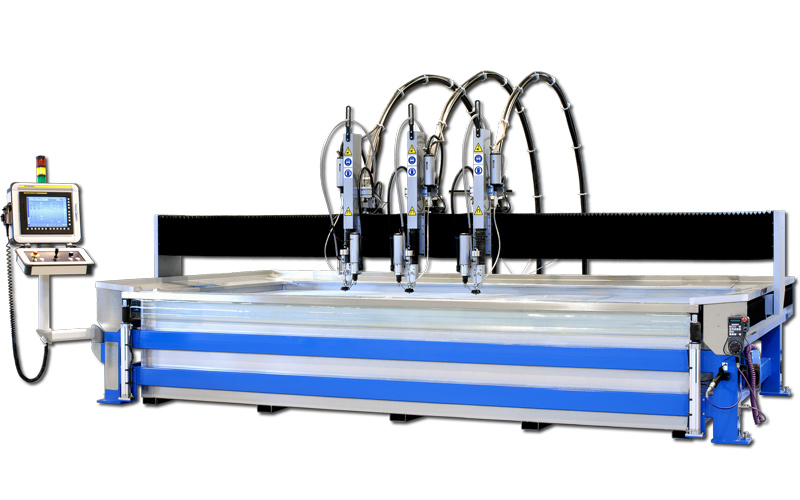

Premium & Grand

Bespoke and versatile for long term competitive advantage

Bespoke high end waterjet machines systems with a wide range of optional settings. Multiple cutting tools, 2D, 2,5D or 3D cutting. Pure water, abrasive of fine abrasive cutting. Our worldwide patented guide system for extreme tolerances, independent if it is 6 feet or 40 feet machines.

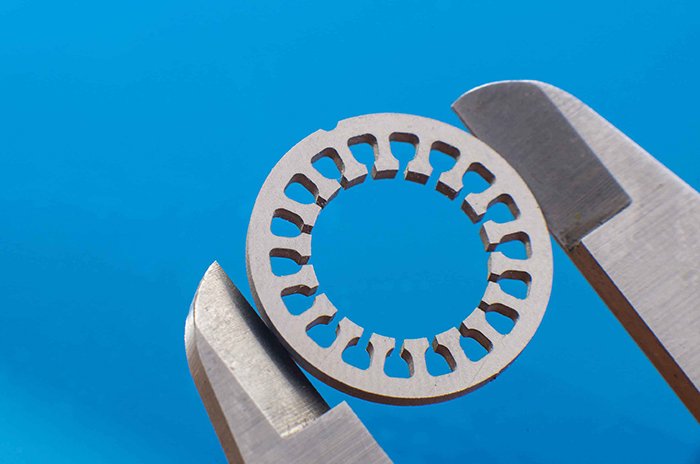

Micro

Ultra-high precision for fine parts and narrow cuts

The Micro machine is designed to deliver the thinnest and most precise cut possible, with a cutting table specifically designed to minimize vibration and thermal influence. Micro waterjet compliments technologies like EDM and Micro Laser, while keeping all the benefits of a waterjet technology.

Water Jet Sweden US Sales Team

Telephone: 1-833 452 4516

E-mail: sales-us@waterjet.se

Lennart Svensson

Christian Svensson

Tony Rydh

Sales contact or book a meeting

Do you want to book a physical meeting with us at one of the upcoming trade fairs or would you like to be contacted by our sales team? Please fill in the form.

News & articles

Read more about Water Jet Sweden FiveX applications in some of our published news and articles.

Finding the right micro waterjet for high tech ceramic parts

Competing for a CERN tender the Spanish company Nanoker Research S.L searched the world to find the right machine supplier.

Grasping the opportunity for a CERN-tender

Winning a CERN tender often means a big contract and stable revenue. To win you need to meet specific requirements with high technical content and also to be price leader.

WJS Tech Day 2023 – forum for frontline fabrication

A cloudy day in October, a group of people from different parts of Europe visited Water Jet Sweden’s headquarters in Ronneby.

New machine to Sweden’s largest growth region

In 2022, Swedish government estimated a total of 40,000 new jobs in in Norrbotten and Västerbotten region, in the norther territory of Sweden.

New technology simplifies the manufacture of jet engines

When fabricating jet engine turbines, Wire EDM is often used, since the technology provides narrow cuts for precise and complex shapes.

New precision waterjet for medical implant production

Medical implants are a growing sector within the healthcare industry. Quality of life is improved for millions of people every year.

30 years in the forefront of waterjet cutting technology

As co-founder and designer of Water Jet Sweden’s reputable waterjet cutting systems Tony Ryd has been there from the start.

Mission Completed! A full-size 3D waterjet to Radius Aerospace.

Elizabeth Robison, project manager at Radius Aerospace, defied the snowy winter and traveled from Hot Springs, Arkansas USA, to Ronneby, Sweden with one mission – to supervise the Factory Acceptance Test.

The first FiveX Ultra is already ordered!

Just over a month ago, Water Jet Sweden launched the new machine concept FiveX Ultra and the first order has already been signed.

Now FiveX Ultra is here!

FiveX Ultra, model name NC5 Ultra, change the scene of 5-axis waterjet cutting.

Like brand new after 21 years

“Quality goes never out of style,” they say. Sometimes quality seems to never go out of performance either.

Redefining full 3D abrasive waterjet cutting

Each FiveX machine system is a unique solution based on specific customer requirements. Built on the same platform but bespoke in width, length, height and set of features.

Micro waterjet bridges the gap between EDM and Micro Laser

Cutting narrow incisions with ultra-high precision in high density materials using waterjet technology requires a specific waterjet cutting process: the Fine Abrasive Waterjet process (FAWJ).

Micro and small waterjet cutting machines

In recent years, several machine manufacturers launched machines under the category Micro. When you look closer it is evident that the meaning of Micro differs greatly between manufacturers.

Waterjet Technology solves future Rocket Science

In Sweden you find the world leading supplier of Payload Adapters and Separation Systems for commercial launch vehicles.

Soon in Chicago: Step right into a waterjet – while it’s cutting.

Water Jet Sweden has long been recognized for manufacturing the industry’s most advanced, high-quality water jet systems.

Shaping 3D parts with free form abrasive waterjet cutting in space

High Tech Industries need to make 3D parts in hardened metals, special alloys and composite materials with accurate, high precision cuts.